Services Akhila Labs

MANUFACTURING & INDUSTRIAL IOT

SOLUTION

Transforming factories and industrial plants with real-time production monitoring, predictive maintenance, energy optimization, and autonomous quality inspection powered by IoT sensors, edge AI, and cloud analytics.

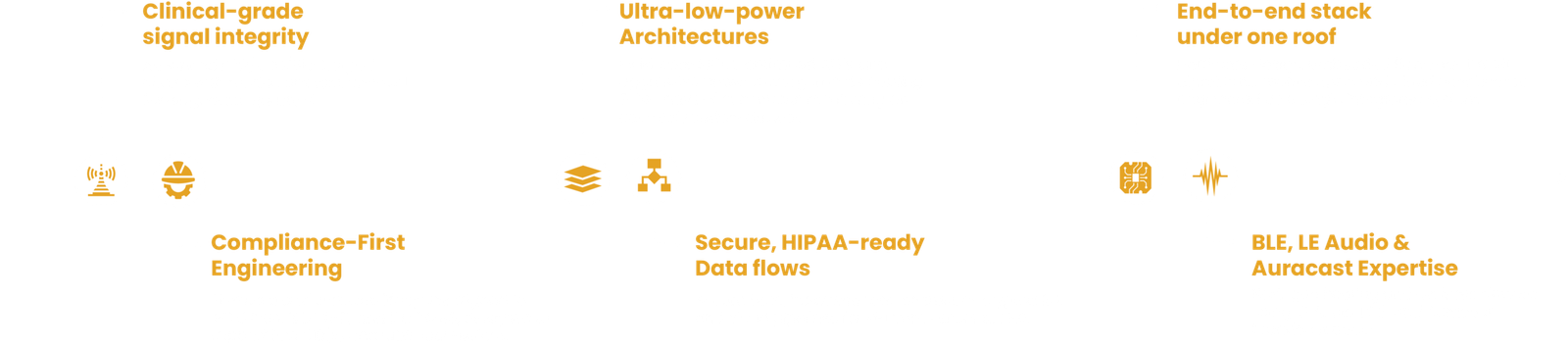

Key Value Propositions

Akhila Labs delivers compliance-first, medical-grade wearables with end-to-end engineering for

fast, regulatory-ready, and scalable digital health solutions.

Industry Problem

Statement

Modern manufacturing is under constant pressure to boost efficiency, maintain high product quality, and achieve sustainability goals, all while managing aging equipment and integrating legacy systems.

Modern manufacturing faces pressure to improve efficiency, quality, and sustainability whilemanaging aging equipment and legacy systems

![]()

Real-time production visibility

Live OEE, throughput, and defect rates across production lines and equipment.

![]()

Predictive maintenance

Vibration, temperature, and acoustic anomaly detection preventing unplanned downtime before it happens.

Autonomous quality inspection

On-line vision and sensor-based defect detection, replacing manual inspection with instant feedback to the line.

Energy optimization

Equipment-level consumption monitoring and demand response, reducing operating costs by 15–25%

Legacy system integration

Bridge aging PLCs, SCADA, and MES platforms without costly replacement; extract actionable data from disparate systems.

Closed-loop automation

Real-time feedback loops for parameter tuning, reducing waste and improving product quality.

Our Solution

Approach

Equipment & Production Data Collection

We help modernize manufacturing operations by retrofitting legacy equipment with non-invasive sensors—vibration, thermal, acoustic, and current—without altering existing control systems. Real-time, time-stamped data acquisition ensures synchronized insights, even with intermittent connectivity.

![]()

Retrofit aging equipment

- Non-invasive sensors (vibration, thermal, acoustic, current) on legacy machines without modifying control systems.

![]()

Real-time data acquisition

- Synchronized time-stamped data from all equipment; buffering for intermittent connectivity.

![]()

Protocol bridges

- Gateways translating Modbus, OPC-UA, Profibus, and CANbus tomodern MQTT/REST, enabling legacy systems to coexist with new platforms.

Edge Analytics & Local Optimization

Local Optimization Through Edge Analytics

Our edge analytics solutions enable real-time defect detection using vision systems and acoustic or vibration sensors with TinyML models running locally on edge devices, providing instant feedback to the production line. Continuous equipment health monitoring identifies anomalies such as bearing wear, misalignment, or lubrication issues, generating alerts weeks before potential failures.

Cloud Analytics & Intelligence

Cloud-Based Analytics for Smarter Decisions

Energy dashboards provide visibility at line, equipment, and facility levels, with comparisons to baselines and peer plants. Automated root-cause analysis correlates events with equipment states, material batches, and operator actions, while KPI benchmarking and smart alerts enable performance monitoring against targets, industry standards, and the plant’s best practices.

MES & ERP Integration

Seamless MES and ERP Integration

Our MES and ERP integration connects real-time production data—including counts, defect rates, and cycle times—directly to MES systems for scheduling and tracking. Material traceability is enabled through barcode and RFID systems, linking finished goods to material batches, equipment states, and operator IDs for quality control and recall readiness.

Workforce Enablement & Decision Support

Empowering Workforce with Decision Support Tools

Our workforce enablement solutions provide mobile operator apps with real-time dashboards displaying line status, alerts, and recommended next actions. AI-powered insights explain anomalies—such as elevated conveyor motor temperatures or slowdowns—helping operators quickly understand and respond to issues.

Use Cases & Applications

Akhila Labs supports a wide spectrum of healthcare and wellness applications:

Automotive assembly

Real-time torque, pressure, and position monitoring during welding, fastening, and assembly; defect detection before the next workstation.

Energy-intensive industries

Equipment-level energy consumption monitoring and demand response to reduce peak loads and costs.

Food & beverage processing

Temperature, humidity, weight, and flow monitoring; traceability from raw material through packaging for recall management.

Textile & apparel

Defect detection in fabric (color, weave, tears) and garment assembly (seams, fit) before shipping.

Electronics manufacturing

Solder joint inspection, component placement verification, and test coverage tracking to reduce scrap and rework

Packaging & labeling

Label placement verification, barcode readability, and package integrity checks.

Pharmaceutical production

Environmental monitoring (temperature, humidity, particle counts) and batch genealogy for regulatory compliance (21 CFR Part 11).

Disaster response

Distributed sensors detecting flooding, earthquakes, and air quality, enabling rapid emergency response.

Discrete manufacturing (machining, stamping)

Tool wear detection, dimensional measurement, and surface finish monitoring to reduce scrap.

Clinical Trials & Digital Biomarkers

Multi‑modal patches and sensor kits that capture continuous biometrics and behavioral data for decentralized trials.

Technologies & Tool

Sensors & Hardware

Vibration (accelerometers), temperature (thermal cameras, thermistors), current (clamp meters), pressure, flow, vision cameras, acoustic sensors, RFID/barcode readers

Connectivity

Ethernet (wired, for reliability), Wi-Fi (for edge devices), cellular (backup/remote plants), LoRaWAN/NB-IoT

Edge Platforms

Siemens SIMATIC, Beckhoff, Kontron, Advantech, or custom Linux/Docker-based gateways

Cloud Platforms

AWS, Azure, GCP, or on-premises with InfluxDB, Grafana, and custom analytics engines

MES/ERP Integration

SAP, Oracle, Microsoft Dynamics, custom APIs, OPC-UA bridges

AI/ML

TensorFlow, PyTorch, scikit-learn, edge inference on Jetson for real-time defect detection

Frequently Asked Questions

At Akhila Labs, embedded engineering is the foundation of everything we build. We go beyond writing firmware that runs on hardware—we engineer systems that extract maximum performance, reliability, and efficiency from the silicon itself.

How do you handle the IT/OT security boundary?

Network segmentation, VPNs for remote access, role-based access control, and audit logging. We follow NIST Cybersecurity Framework and align with IEC 62443 (industrial security standards).

What is a typical ROI timeline for an IIoT project?

Pilots (3–6 months) typically show 20–30% improvement in one KPI (e.g., downtime, energy, crap). Full rollout (6–12 months) pays back in 1–2 years through compounded savings across all lines and facilities.

Can your platform talk to our existing MES or ERP?

Yes. We integrate via REST APIs, OPC-UA, MQTT, or direct database connections. We're experienced with SAP, Oracle, Siemens, Dassault, and custom systems.

How do you ensure data quality from sensors?

Sensor validation (check plausibility), outlier detection, missing data handling, and time-stamping validation. On-device filtering removes noise before sending to cloud.

Can the system scale to multiple plants?

Yes. Cloud architecture supports unlimited plants and equipment. Standardized sensor packages and gateway firmware accelerate rollout to new sites.

What is the typical cost per equipment for IIoT monitoring?

$500–$2,000 per equipment depending on sensor types and integration complexity. ROI typically achieved within 6–18 months for critical equipment.

How do you handle equipment-specific algorithms (e.g., different presses)?

We build universal feature extractors (FFT, statistical features from sensor data) that work across equipment types, then fine-tune models for specific machines and failure modes.

Subscribe to the Akhila Labs Newsletter

Get the latest insights on AI, IoT systems, embedded engineering, and product innovation — straight to your inbox.

Join our community to receive updates on new solutions, case studies, and exclusive announcements.